about us

Effective Quality Management

A robust quality control process catches potential issues early, protecting the product’s reputation and the brand’s image. To ensure product integrity and boost consumer satisfaction, quality control in packaging must be a key element of any business strategy.

Material Selection

Suppliers Risk Management

In the custom packaging industry, the reliability of raw materials is foundational to our success. Supplier Risk Management (SRM) serves as a strategic approach to evaluate and mitigate risks associated with our raw material suppliers.

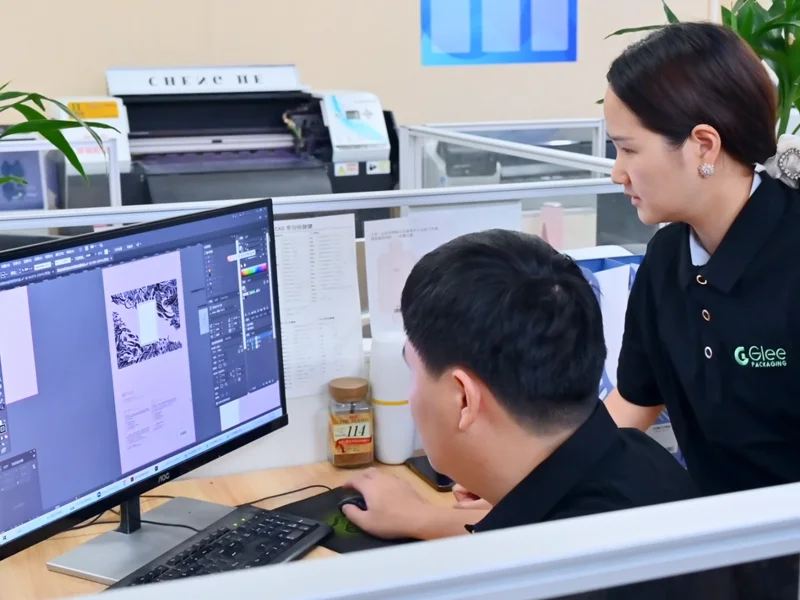

Effective Quality Management

Following ISO 9001 standards, we continually develop and refine our own operating instructions to produce packaging of the highest quality. At each stage of production, we implement specific testing protocols to ensure uncompromising quality. Additionally, as an FSC-certified company, Gleepackaging sets itself apart in the packaging industry by prioritizing both excellence and sustainability.

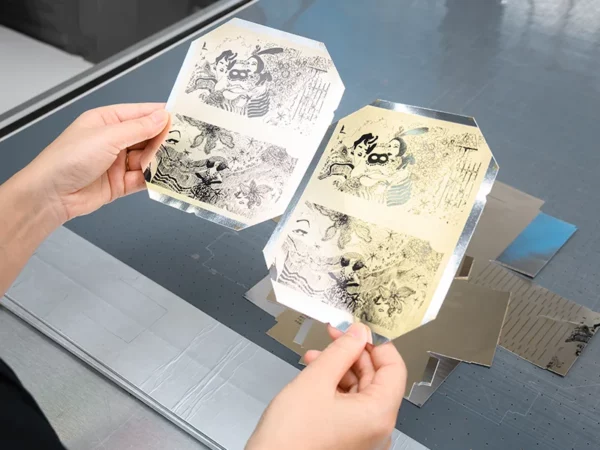

4 way to Packaging Quality Inspection Processes

Superior manufacturing ensures durable, long-lasting packaging. At Gleepackaging, our in-house lab conducts a rigorous 6-step process to thoroughly test and inspect the finished product, upholding our commitment to exceptional packaging quality.

Design and Structure

Enhance any design by leveraging our design expertise to suggest improvements and elevate it to a better version.

Size and Weight

NexGenPacks provides all standard sizes and offer a wide range of paper weight options that can be tailored to meet the client's specific needs.

Sample Checks in Production

Work closely with clients to modify the prototype, achieving a design that meets market requirements.

Quality of Print

Cooperate with clients to make changes to the prototype to arrive at a design that suits market needs.

Finish Inspection for Every Product

Based on the product types and techniques used, subsequent inspections target various aspects, focusing on potential defects. Every piece of packaging undergoes this thorough process.

Shelf Life and Storage Conditions

- Shelf Life Determination

Packaging plays a crucial role in determining a product’s shelf life. It must safeguard the product from environmental factors that could cause deterioration and shorten its lifespan.

- Storage and Transportation Considerations

Factors such as the size and shape of the packaging, its durability under different temperatures, and its ability to endure transportation stresses are essential considerations.

- Consumer Handling

Packaging must be durable enough to endure repeated consumer handling, including opening and closing, without breaking or damaging the product.

Product Safety

- Contamination Prevention

Packaging must act as a barrier against external contaminants like moisture, bacteria, and light. The choice of materials and design should be tailored to the product's specific requirements to ensure its safety.

- Tamper-Evident Packaging

Tamper-evident packaging boosts customer confidence by clearly indicating if the product has been compromised.

- Storage and Transport Conditions

The packaging must endure the storage and transportation conditions, including temperature and humidity. If it fails to do so, the product may spoil or become damaged.

Environmental Impact

- Sustainable Packaging

Sustainable packaging reduces the environmental impact and can appeal to eco-conscious consumers. Considerations include the use of recyclable or biodegradable materials and minimizing packaging waste.

- Recycling and Disposal

Packaging should be designed with end-of-life disposal in mind. Clear instructions for recycling or disposal can help consumers dispose of the packaging responsibly, reducing its environmental impact.

Share Your Concerns for A New Packaging Solution

Packaged to make Perfect. NexGenPacks is here to help you with a solution that connects your brand to a broader market.